CRU's Battery Technology and Cost Model

The Energy Transition is driving unprecedented demand for batteries, with new chemistries emerging each year, aimed at reducing costs, improving performance, or both, staying informed is imperative to capitalise on emerging trends, navigate technological advancements effectively, manage procurement and risk and grow financially and strategically. CRU's Battery Technology and Cost Model offers unparalleled data and analysis capabilities, empowering businesses within the battery space to make strategic decisions.

Data, Insight and Expertise: The regularly updated Model is powered by CRU’s deep understanding of raw materials and Exawatt’s unparalleled knowledge of battery technology.

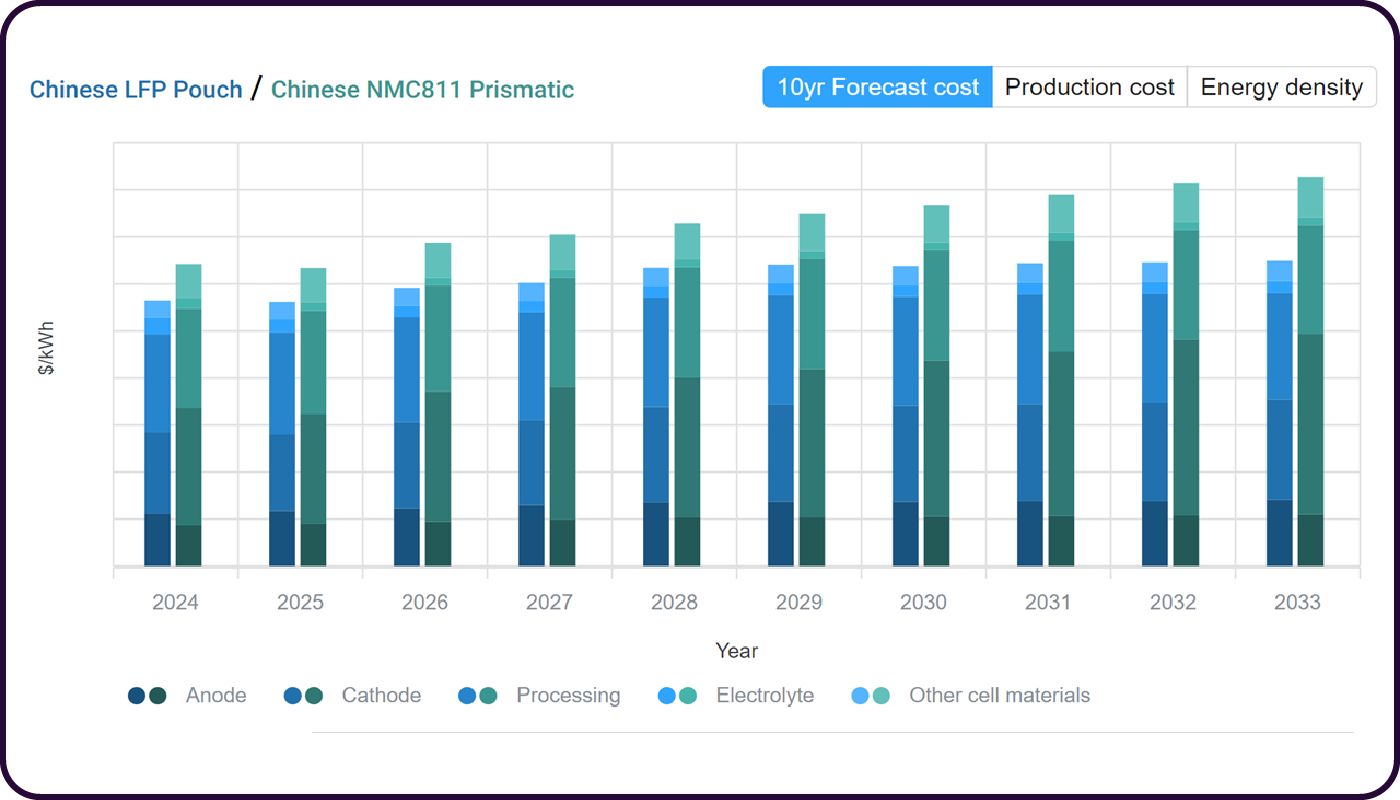

Fully Customisable: The Model is, a user-friendly online tool that enables analysis, comparisons, and forecasts for battery production costs and performance by technology, company, location, and raw material prices for hundreds of different batteries, including next-generation cells.

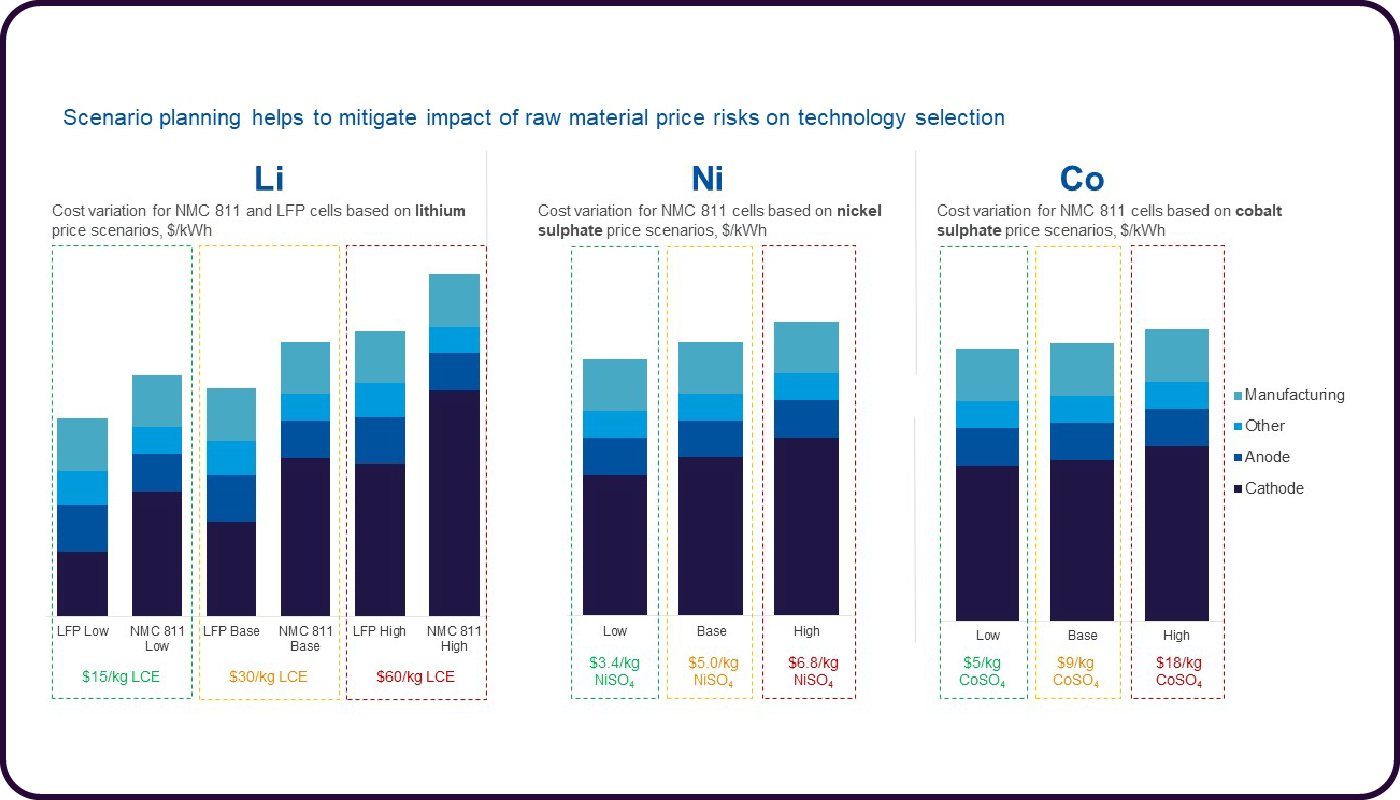

Run Scenarios and Compare Technologies: Forecast interchangeable production costs and key performance metrics, including energy density, across different technologies. Rapidly run bottom-up, granular scenarios examining how changes in key inputs, including raw material prices, change final cell costs.

Flexibility: As an alternative to using the in-built specific battery technologies, the fully customisable online tool allows input of battery chemistries, cell formats, component attributes, production methods, plant sizes and locations.

Key Features of the Battery Technology and Cost Model

- Model hundreds of battery technology combinations

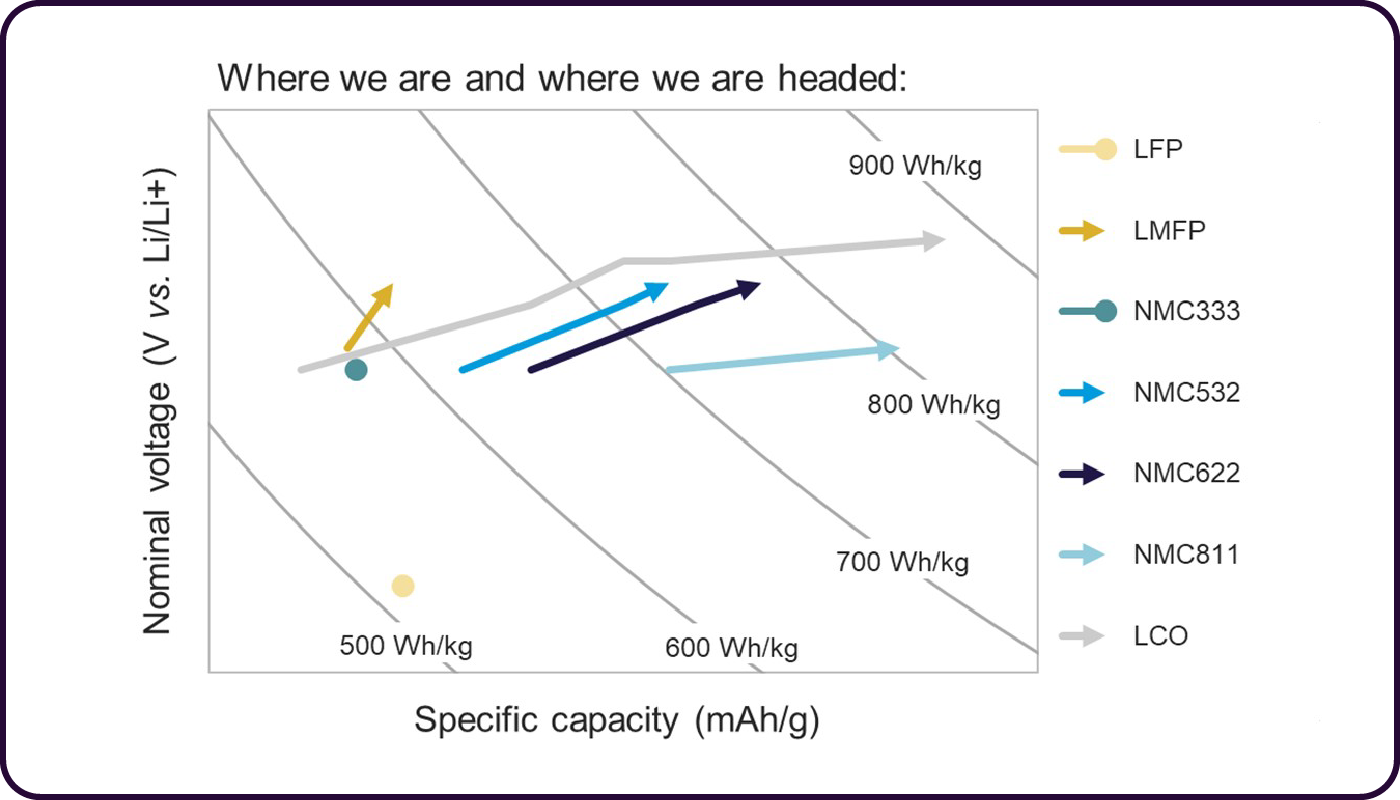

- Benchmark battery technologies, comparing energy density and production cost over a ten-year forecast, including next-generation cells

- Easily run scenarios, efficiently model how changes in parameters, including raw material prices, change cell costs

- Manage, review, and update your own battery technologies in a dedicated online interface

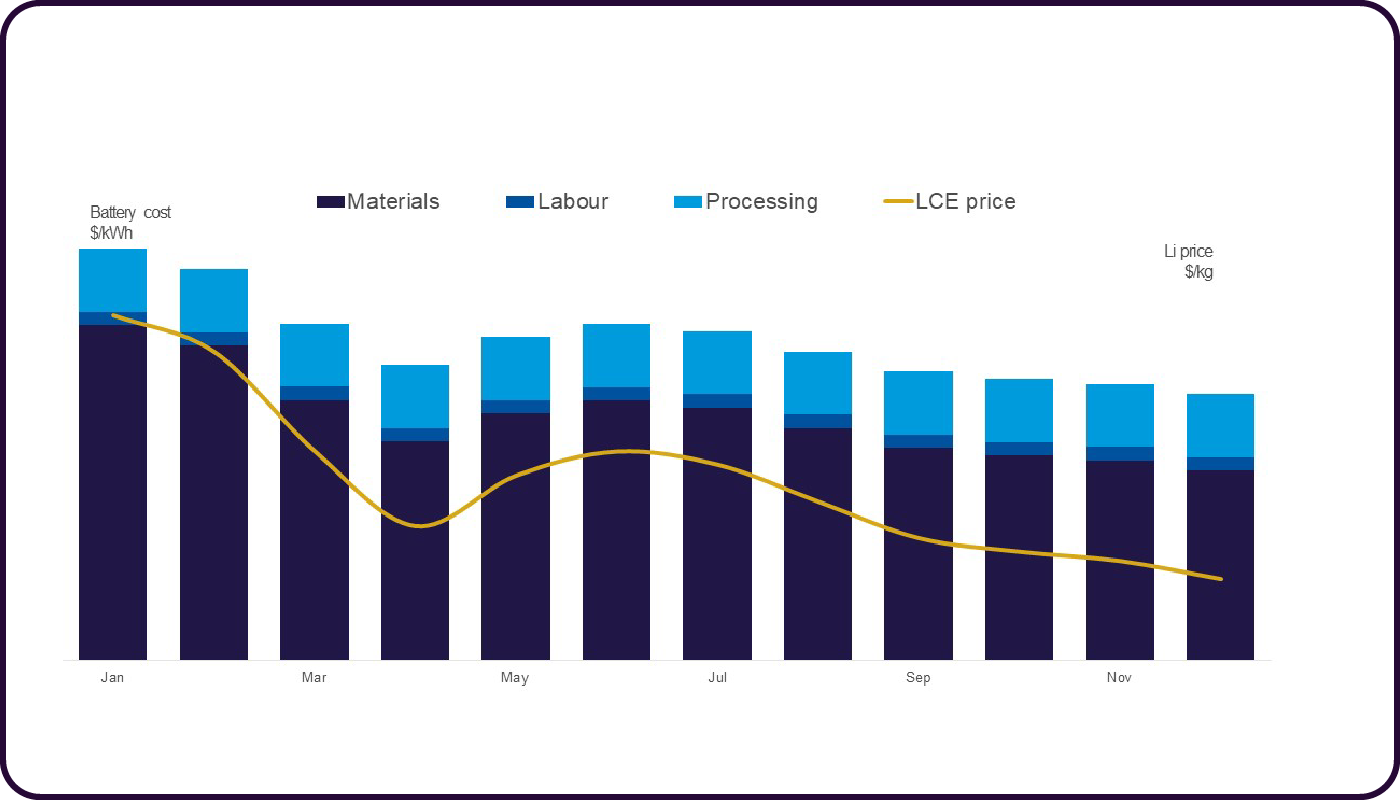

- Review our forecasts for key metrics, including raw material prices, over a ten-year forecast using CRU data

- Coverage of all key markets: select from China, USA, Europe, South Korea, Japan, the UK, and Canada, comparing labour rates, labour cost, electricity cost and production yield by country

What does the future hold for battery costs?

Understand raw material challenges, battery industry insights, and the critical role of cost analysis. Join our webinars, navigate the dynamic global landscape and explore industry shifts.

Register hereAt CRU, we understand that modelling costs for batteries can be arduous and time-consuming. Our Battery and Technology Cost Model allows you to run scenarios and comparisons to benchmark and forecast performance and cost for different chemistries, with ease.

Why choose the Battery Technology and Cost Model?

Battery Manufacturers

Optimize decision-making, reduce costs, and maintain competitiveness in the dynamic battery market landscape.

Detailed understanding of costs at the cell level.

Forecast raw material price fluctuations and enable precise quantification of these risks, with comprehensive market insight.

Benchmarking against competitors, identify new opportunities, guide R&D and production efforts.

Foresee requirements for procurement planning and cost control.

Book a demo

Financials and Investors

Insights, opportunities, and trends into complexities of the battery value chain to capitalize on emerging opportunities.

Save valuable time and resources spent on data collection and analysis.

Forecast which technologies and producers are poised to gain market share.

Accurately model market size for competing technologies and evaluate associated risks in project financing.

The scenario analysis enables easy access to assess project viability, manage risk, and maximize potential returns to support informed lending decisions.

Book a demo

Policymakers and Intergovernmental Associations

Scenario plan costs of production to design and review policies, ensure industry growth and supply chain resilience.

Understand the cost interconnections between shifting technologies, supply chains and raw material markets.

Recognize the impact on manufacturing costs for battery producers and end users.

Navigate geopolitical risks in the battery industry and energy markets while staying informed about relevant drivers and technology costs.

Book a demo

Utilities and Renewable Energy Owners and Operators

Insights into costs and technology evolution, model the cost differentials between cells, and understand trends driving this growing market.

Forecast the costs of energy storage and model the technologies which will enable it.

Simplify complex processes and recognise financial and technological risk.

Optimise procurement processes and ensure informed decision-making on current and future battery technologies, ensuring maximum returns.

Book a demo

Automotive

Unparalleled insight into how technology changes and raw materials will affect battery costs over a ten-year forecast, helping you predict supply chain changes and challenges.

Rapidly run bottom-up, granular scenarios over a ten-year timeframe, manipulate raw material prices and change final cell production costs.

Guide your procurement planning.

Support risk management, supplier negotiations, cost planning, and purchasing strategies.

Inform investment plans, ensure future-proofed strategies, and drive competitive advantages.

Book a demoBattery Technology and Cost Model Team