Germany’s K+S cut the blue ribbon on its Legacy Project potash mine in Saskatchewan, Canada on 2nd May ahead of production of its first marketable tonnage expected in June.

The mine, which was renamed “Bethune” at the opening ceremony, is the first potash operation to be commissioned in the province in over 40 years. K+S’s first North American production facility arrives as potash prices languish at their lowest nominal values for a decade. The mine is the largest single investment in the company’s history with capital expenditure totalling $4.1 billion CAD (about US$3.6 billion overall). It contains 160Mt of proven and probable reserves grading at 29% KCl (or 18% K2O) with an expected mine life of around 50 years.

The 2016 edition of the CRU Potash Cost Report analyses the future costs of all major projects expected to commence production before 2021 and anticipates that K+S faces profitability challenges at Legacy due to high capital recovery and processing costs.

Solution Mining in Saskatchewan

The Legacy Project mine will not use underground continuous mining methods more commonly employed in the region but will instead operate as a solution mine. Of the 9 currently producing mines in the province, only Mosaic’s Belle Plaine and PotashCorp’s Patience Lake use solution mining, with the latter forced to convert from conventional mining methods following severe flooding in 1987.

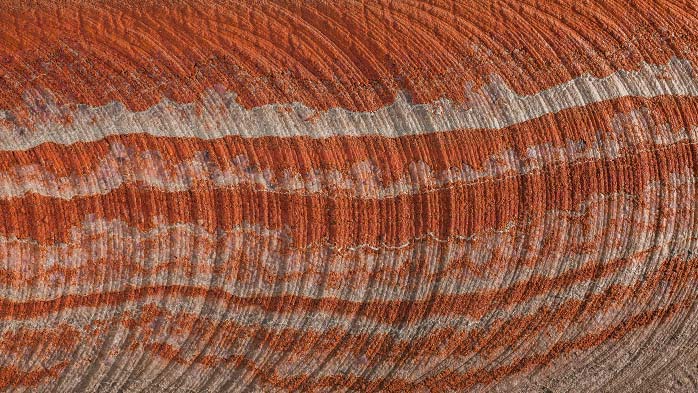

Solution mining has been in use since the 1960s in Saskatchewan and the method remains broadly unchanged. In essence, water or brine is fed down a borehole to an identified sylvinite or halite bed; the fluid dissolves the soluble sylvite (and sometimes the halite as well) forming a cavern and the sylvite-bearing fluid is pumped to the surface for processing by crystallisation.

Solution mining is cheaper in terms of capital investment and operationally in the mining phase than conventional underground mining. It never requires personnel to work underground, equipment is simpler and the surface footprint of the mine is generally smaller. Its major disadvantage lies at the processing stage as cheaper flotation cannot be used because the sylvite arrives at the surface as a brine, not as a solid which is required for flotation. Therefore crystallisation, which is typically more energy intensive and slower, must be utilised. Crystallisation also yields white KCl rather than the red variant produced by flotation. Colour has no effect on efficacy of KCl as a fertilizer but some Asian consumers have an aesthetic preference for red KCl. Some producers of white KCl consequently colour their product to better serve these markets.

How will Legacy’s costs compare?

Although K+S is well established in Europe, it is new to the Saskatchewan potash market. The region’s operators, PotashCorp, Mosaic and Agrium, are some of the most experienced in the world and competing on costs will be a major challenge. K+S has further complications to break into the US market. The company signed a sales agreement with Koch Fertilizers in August 2015 to distribute 0.45Mt/y (500,000 short tonnes) of Legacy’s annual production to US customers. However, only a month ahead of the mine’s start-up, K+S does not currently appear to have access to any US distribution warehouses, crucial for farmers to procure their fertilizer. The other producers all own extensive US warehouse networks across the US Midwest. Although still unconfirmed, the expectation is that K+S will use Koch distribution warehouses.

Nevertheless, assuming K+S is able to overcome initial challenges, Legacy should prove a competitive potash solution mine. On the 2021 business costs curve, the mine places approximately in the middle of all North American sites and ranks as the lowest cost solution mine, behind Mosaic’s Belle Plaine and Yancoal’s planned Southey facility.

Moreover, Legacy is considerably lower cost than any of K+S’s current European operations and this underpins the firm’s motivations for entering the North American market as a producer. At a company level, the Legacy mine will almost certainly lower production costs (on a per tonne basis). The profitability of K+S’s European potash production has become increasingly marginal due to higher site costs related to low sylvite grades and the production of potash as a by-product. Falling potash prices have exacerbated this situation and the company needs to lower its costs.

Additionally, production at its European sites is becoming increasingly unreliable. In 2016 the company encountered problems with brine waste water disposal at its German Werk Werra facility which resulted in a 0.8Mt shortfall in total production (of all products). Legacy should impart greater stability to its production totals and, hypothetically, its earnings.

However, operating costs only reveal part of the story. By including capital expenditure recovery over the life of the mine, or a large portion of it, CRU estimates that Legacy would place at the top of the economic cost curve.

K+S is therefore relying on potash prices returning to values last witnessed in late 2013 to profit from its North American venture. However, as the mine is only one of a number of greenfield projects and brownfield expansions scheduled to enter production within the next five years, many other producers will be hoping for the same scenario. With so much additional capacity set to enter the market it’s not currently clear how or, most crucially, when any market stimuli are likely to originate.