This is part 1 of CRU’s Insight series titled “CRU explains: All you need to know about Indian iron ore” – available to CRU subscribers. Part 2 of the series covers costs and ore quality, and Part 3 focuses on how Indian iron ore demand will change and why the country will become increasingly dependent on iron ore imports. If interested in accessing Parts 2 and 3, please contact us or request a demo for our services here.

On 11 September 2025, CRU will host two webinars where we will present our views on the future of Indian iron ore. Please go to the bottom of the page to register for the events.

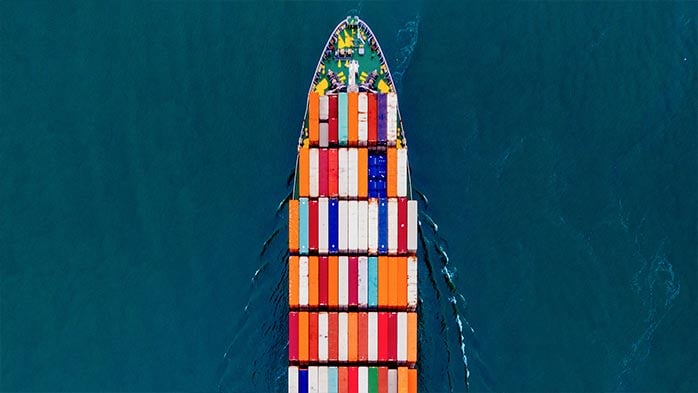

According to CRU’s Iron Ore Market Outlook, India ranks as the world’s fourth largest iron ore producer, with production reaching 261 Mt or 282 Mt of run-of-mine (ROM) in 2024, equivalent to 11% of global production. Over the past two decades, Indian iron ore production growth has gradually shifted from being export-driven to meeting rising domestic demand. While the country has remained an iron ore net exporter, average annual exports have fallen from 72 Mt/y during 2005–2014 to 28 Mt/y during 2015–2024. In 2024, India accounted for only 2% of world iron ore exports.

Looking ahead, although Indian iron ore production is expected to grow further, exports are likely to fall due to growing domestic demand, weakening Chinese appetite for iron ore and rising production costs. Furthermore, we expect a wave of consolidation in the Indian iron ore market, with top producers expanding their market share through the acquisition of recently.

In this Insight, we will take a closer look at:

- The structure of Indian iron ore supply, with a special focus on India’s ‘Big 5’ producers, which are increasing their dominance of Indian iron ore supply

- How India’s mining reform is changing the iron ore supply landscape

- What the consolidation means for domestic iron ore prices and Indian iron ore exports

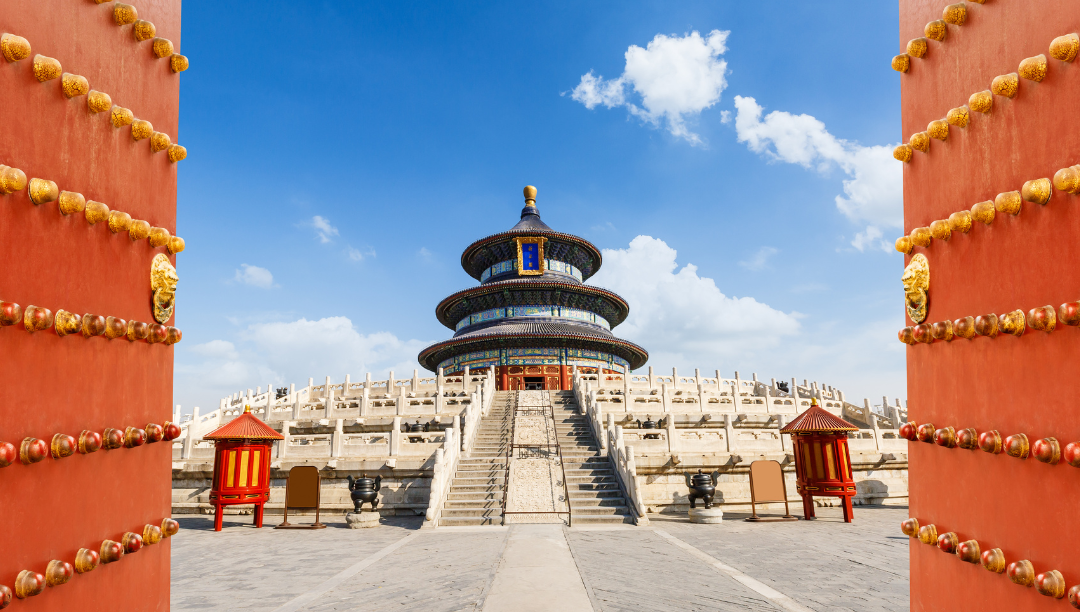

Indian iron ore supply concentrated to four states

The 282 Mt of Indian ROM production in 2024 marks a near doubling of 2015 production levels. This growth has primarily been driven by rising domestic crude steel production, which rose from 86 Mt in 2015 to 145 Mt in 2024, according to data in our Iron Ore Market Outlook. In contrast, from 2005 to 2015, we saw a decline in iron ore output as the industry was heavily reliant on exports, especially from the small state of Goa on the west coast. During this period, frequent policy changes disrupted export flows, leading to a dramatic fall in export volumes.

Four states – Odisha, Chhattisgarh, Jharkhand and Karnataka – account for more than 90% of India’s iron ore production. Odisha, on the east coast, is the largest of them all, accounting for over half of India’s iron ore production. At the same time, Goa has essentially stopped exporting iron ore. The state was the largest iron ore-exporting state prior to 2012, but new environmental regulation has brought the state’s production down close to zero.

Mining reforms redrawing Indian iron ore supply landscape

India’s iron ore mining sector consists of three distinct ownership structures:

- State-run miners

- Private miners that obtained mining leases before 2015 and are still in operation

- Private miners who acquired mines after 2015

In 2015, India carried out a mining reform that marked a significant turning point in the country’s iron ore industry – the introduction of the amended Mines and Minerals (Development and Regulation) Act (MMDR). The reform established a transparent auction-based system for allocating mining rights. This applies only to private companies, while state-run entities continue to receive direct mine allocations. This shift triggered a wave of aggressive bidding, particularly among private steelmakers seeking to secure long-term raw material supply to support their growing steel capacities.

Intense competition during the auction process significantly inflated bidding levels, leading to elevated production costs. Successful bidders are required to pay an ‘auction premium’ for every tonne of iron ore they mine, similar to most countries’ royalty schemes. However, miners are also required to pay regular royalty fees, in addition to the ‘auction premium’ that was set for each mine during the auctioning process. As a result, many private merchant miners, especially those without downstream integration into value-added products are struggling to bring their auctioned mines to operation simply because the costs are too high.

Today, the only low-cost producers in the private sector are the ones who acquired the mines before 2015 when the MMDR was implemented. These miners do not need to pay any ‘auction premium’ to the government. However, mining leases of most such mines are expected to expire in 2030. Thereafter, these mines will also go through the MMDR auctioning process to find new buyers. This will lead to cost inflation for those mines after 2030.

In the auction processes taking place thus far, the competition for mining leases has been extremely fierce. In fact, many mines have been auctioned out, with the ‘auction premium’ settling at levels exceeding 100% of the market price. In the future, we expect this fierce competition to continue, driven by steelmakers’ strong desire for supply security. However, the complex cost structure means that private merchant miners are unlikely to turn a profit solely by selling iron ore. As a result, the likely winners of new auctions will be miners having downstream operations. This trend will accelerate the restructuring of the Indian iron ore market, leading to a consolidation among the ‘Top 10’ miners. State-run and private miners with downstream facilities are projected to increase their share of production to 85% while private merchant miners will gradually be pushed out of the market.

Merchant producers face cost pressures from mining reforms

In 2024, there were 182 iron ore mines operating in India. Production was highly concentrated, with 78 mines accounting for ~94% of total output. Among the 78 mines, 26 were operated by three state-run companies that accounted for ~40% of India’s iron ore production in 2024:

- SAIL: India’s largest state-owned steelmaker

- NMDC: A state-owned company and India’s largest iron ore miner

- OMC: The largest merchant iron ore miner in Odisha

These state-run iron ore mines benefit from direct government allocations and are exempt from auction-related premia, giving them a clear cost advantage over private operators. However, if state-run mines get a mine allocation, or the lease of existing mines is renewed, then applicable royalties on such production would be 37.5% compared to the previous 15%.

Since 2015, the Indian government has successfully auctioned out 130 iron ore mines. Most of them have been acquired by miners at high bids to ensure supply security for future consumption. If a company bids at an 80% ‘auction premium’, this means that for every tonne of iron ore they produce, they will need to pay a premium of 80% of the market price for domestic iron ore to the government. On top of this, they will also have to pay regular royalties. In other words, the higher the bid, the higher the iron ore production cost will be. Out of 130 mines auctioned so far, 100 mines were acquired for a premium level of over 80%

From 2015–2024, only 36 out of 130 auctioned mines have become operational. The high costs associated with the elevated ‘auction premia’ are seen as the main reason for this failure to bring mines online.

Most miners who are struggling to commence operations are private merchant ones who acquired mines with bids as high as 100% or higher. Making profits with such high ‘auction premia’ is extremely difficult unless these miners have forward-integrated operations such as pellet plants, DRI plants or steel mills to pass on the higher costs to. We explain this dynamic in more detail in the full insight series available to CRU subscribers (if interested please contact us or request a demo for our services here).

Those 36 auctioned mines, which have successfully started, are mostly owned by companies that have downstream DRI or steel operations.

For the mines that have yet to start, we expect that most of them, that have been acquired by merchant miners, will simply be surrendered back to the government due to economic unviability. Furthermore, even in future auctions of iron ore blocks, miners who have downstream operations such as pellet plants, DRI or steelmaking for captive consumption will emerge as the successful bidders. This will eliminate the private merchant miners from the Indian iron ore market and consolidation will intensify.

Indian iron ore production is consolidating with big miners

India’s ‘Big 5’ iron ore producers accounted for 54% of total iron ore production in 2024. This share will rise to 66% in 2030. The ‘Top 10’ producers (including the ‘Big 5’) accounted for 70% of the production in 2024, and CRU expects this share to rise to 84% in 2030.

The ‘Big 5’ comprised of three state-run companies – NMDC, SAIL and OMC – and two private steelmakers – Tata Steel and JSW Steel. Among the next five, which are part of the ‘Top 10’, AMNS, Vedanta and JSPL all have their own BFs and therefore consume almost all of their own iron ore production. Rungta and Lloyds both have small-scale steel operations, but consistently produce more iron ore than they can consume. They are therefore active sellers of iron ore in the merchant market.

Low-cost export bound supply is shrinking

Indian iron ore exports are highly sensitive to seaborne iron ore prices. Generally, high-cost miners who participate in the export market start losing money when the 62% Fe fines price falls below $100 /t, CFR China. Our cost analysis on Indian export-bound supply shows that almost 18 Mt/y of iron ore supply exits the export market once the price falls below $100 /dmt. Lower-cost miners and pellet producers will still actively sell their products in the export market, and we estimate they can supply 30 Mt/y iron ore even if prices fall to $90 /t. Within this group of supply, there are different thresholds for when they will make the decision to stop exporting.

So, who are these low-cost miners that will remain in the market even if prices fall? They are mostly private iron ore miners who acquired the mines before 2015, meaning they do not pay any ‘auction premium’. These miners usually have excess iron ore available, after having sold volumes to the domestic market.

Among the ‘Top 10’ producers, the lowest-cost exporters are:

- Active exporters: Rungta Mines and Vedanta

- Opportunistic exporters: JSW Steel and ArcelorMittal-Nippon Steel (AMNS) are considered as the majority of their mines (acquired through post-2015 auctions) have relatively high production costs. Given their large domestic steel operations, they only have surplus iron ore after meeting captive consumption, and will only export when seaborne price are high enough.

- Others: The remaining companies include state-run companies, Tata Steel, and Lloyds. They do not export iron ore.

Indian iron ore exports to fall as the ‘Big 5’ consolidate

India’s unique iron ore landscape is set to drive industry consolidation, which will reshape the country’s iron ore supply side. Our analysis shows that Indian iron ore exports will fall in the coming years, for the following reasons:

- Growing consolidation of production among large producers that have no interest in exporting iron ore. Instead, their aim is to provide steady supply for the country’s own steel industry.

- Reduced supply from merchant miners, which will result in rising Indian iron ore prices and will incentivise more domestic sales at the expense of exports.

- As mines continue to be allocated through the auctioning process, the average production costs in India will rise. That reduces the country’s competitiveness, and will put further pressure on India’s iron ore exports.

In addition, the government wants miners to beneficiate at least 80% of the low-grade iron ore production to an iron content of 62% or higher. However, this policy is still under discussion and miners are opposing this policy given challenges associated with beneficiation in India and high capex requirements for setting up new beneficiation units. If this policy is implemented, availability of low-grade ore in India will fall, which will further constrain exports of this product.

What’s next?

The unique landscape of India’s iron ore industry will lead to increasing consolidation among major players, paving the way for a more defined and structured market. Meanwhile, mining reforms are expected to raise production costs for merchant miners, at a time when seaborne iron ore prices face downward pressure, ultimately challenging the viability of exports.

As India navigates these changes, key questions remain – to what extent will these shifts impact Indian iron ore trading? And how will the country adapt to global decarbonisation trends given its reliance on low-grade reserves?

In the full insight series, available to CRU subscribers, we explore these issues in depth and explain why India simply cannot rely on domestic iron ore in the future. If interested, please contact us or request a demo for our services here.

Register for our "Indian iron ore - all you need to know” webinar on 11 September 2025 here: