The automotive industry accounts for approximately 10% of end-use sector zinc demand, in the form of galvanised steel sheet, die castings and oxide.

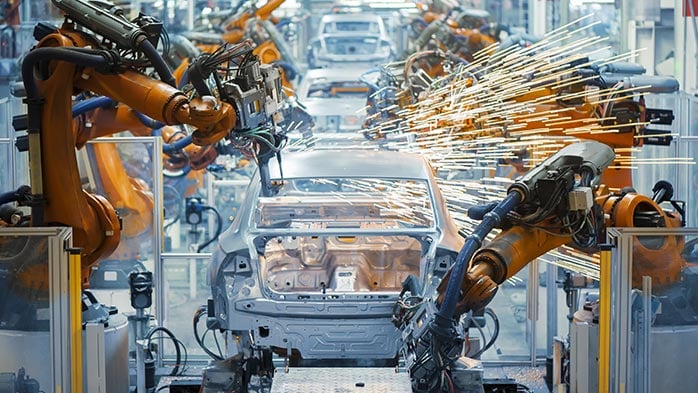

Even before the pandemic, vehicle output and sales in some of the major producing countries were being constrained by new emissions regulations so the industry was already struggling when the Covid-19 pandemic hit. The auto sector was an early victim of Covid-19-related disruption and many automakers were forced to idle production lines due to a breakdown in the supply chain as China went into lockdown in 2020 Q1. This was followed by lockdowns and labour shortages across the globe as the pandemic spread. In this Insight we are looking at the pace of the recovery in the auto and what this means for zinc demand.

Global vehicle output will not recover fully this year

The auto sector has been slower to recover than many others, partly due to structural issues which had become apparent pre-pandemic. Global vehicle output had contracted marginally y/y in 2018 and by 5.7% in 2019, so it is perhaps not surprising that it will not fully recovery this year after falling by 15.6% y/y in 2020. The sector’s performance in the past two years has been even weaker than during the global financial crisis, when vehicle output fell by 4.6% and 12.7% y/y in 2008 and 2009 respectively, followed by a 26% rebound in 2010. In contrast, we expect only a partial recovery in vehicle output this year, of +13.2% y/y.

Fortunately for zinc demand, auto sector weakness has been at least partially offset in many countries by the strength of the recovery in other sectors. We estimate that last year’s slump in vehicle output cost auto-related end-users more than 200,000 t of zinc demand globally and that only ~150,000 t of that will be recovered this year.

Supply chain issues have added to Europe’s auto sector woes

Europe was the worst performer among the major vehicle-producing regions in 2020, with strict Covid-19 lockdowns across much of the continent exacerbating supply chain issues in an already weak market. We now estimate that European vehicle output fell by 22.2% y/y in 2020, following a 4.3% decline in 2019. Our calculations suggest that this equates to the loss of around 80,000 t of zinc demand in galvanising, die casting, oxides and chemicals in 2020.

Hopes of a rebound this year were short-lived as it became clear that European automakers’ reliance on a handful of microchip suppliers has left the industry vulnerable to supply chain issues, which are not going to be quickly resolved. We expect a partial recovery this year (+15.1% y/y) to lift vehicle-related zinc demand by ~40,000 t but do not expect the market to grow relative to 2019 until 2022.

In North America, we estimate that vehicle output contracted by 20.4% y/y in 2020. More than 90% of US automakers closed their plants in early-2020 H2, with some turning to the manufacture of ventilators and other medical equipment to assist in the response to the pandemic. We estimate that North America’s auto sector accounted for the loss of ~70,000 t of zinc demand in 2020.

As in Europe, the recovery has been constrained by supply chain issues and we expect only ~45,000 t of auto-related zinc demand to be recovered this year, based on vehicle output growth of 14.3% y/y. The USA accounts for almost 70% of North America’s auto output and US auto-related zinc demand is expected to exceed 200,000 t this year. Next year, we expect North American vehicle output to exceed 2019’s level, with the auto sector accounting for an estimated 350,000 t of zinc demand by 2022, of which ~230,000 t will be in the USA.

The Asian region is now struggling to contain new Covid-19 outbreaks

In Japan and South Korea, combined vehicle output had reached a plateau of ~13.5 M units/year in 2017-2019, but suffered a steep, Covid-19-related contraction in 2020. This brought combined vehicle output down to 11.5 M units and we estimate that 25,000 t of auto-related zinc demand was lost. In the larger Japanese market, vehicle production fell by 15.5% y/y in 2020. This year, it is expected to grow by 9% y/y but will not fully recover 2020’s losses until 2023. In the smaller South Korean market, the automotive industry employs over 10% of the national workforce and major automakers who were impacted by global dealership closures last year benefitted from government financial and logistical assistance. South Korea’s vehicle output fell by 11.3% y/y in 2020 and, while it will not recover fully this year it is expected to exceed 2019’s level in 2022. We expect combined Japanese and South Korean vehicle output to account for over 200,000 t of zinc demand this year.

In China, auto-related zinc demand accounts for a relatively small portion of overall zinc demand, partly due to lower galvanising rates than in Europe, the USA and North East Asia. We estimate that 55% of steel per vehicle in China is galvanised, as opposed to 80% in developed economies.

Chinese vehicle output peaked in 2017 but fell in 2018 and 2019 as a raft of new regulations led to consumer hesitancy and falling sales. After contracting by 7.3% y/y in 2019, the Chinese auto market bucked the global trend in 2020 and exceeded our forecasts, falling by just 2.2% y/y, with an estimated loss of less than 10,000 t of auto-related zinc demand. This was due in large part to government subsidies and tax cuts and set the Chinese auto industry up for a strong rebound at the start of this year. Although the recovery started to falter in May, we expect vehicle output growth of 6.1% y/y this year to lift auto-related zinc demand to ~335,000 t. By next year, we expect Chinese vehicle output to regain its 2017 high of 29 M units, lifting auto-related zinc demand by a further 30,000 t.

India’s vehicle output fell by 25.5% in 2020 due to Covid-19-related disruption and following an exceptionally weak 2019 (-13% y/y). The proportion of steel which is galvanised in light vehicles in India is still relatively low (30%, compared to 55% in China and 80% in developed countries) and we estimate vehicle output accounted for less than 30,000 t of Indian zinc demand in 2020. This year we expect it to recover to almost 40,000 t.

Brazil is by far the largest producer of passenger vehicles in Central & South America, constituing approximately 86% of regional output. The region was hit hard by Covid-19 disruption last year and vehicle output fell by 31% y/y. Although much of the region is still struggling to contain Covid-19 industrial output has been rebounding and we expect vehicle output to grow by 30.4% y/y this year.

Although the global auto sector is now through the worst of the pandemic-related disruption downside risks remain. Supply chain disruption and record high freight rates continue to constrain the recovery and new Covid-19 outbreaks in parts of Asia have brought new threats. Our current forecast suggests that global vehicle output will not exceed the 98 M units reached in 2017 until 2023 but we expect global auto-related zinc demand to continue to grow despite the ongoing penetration of aluminium autosheet.